Design Features

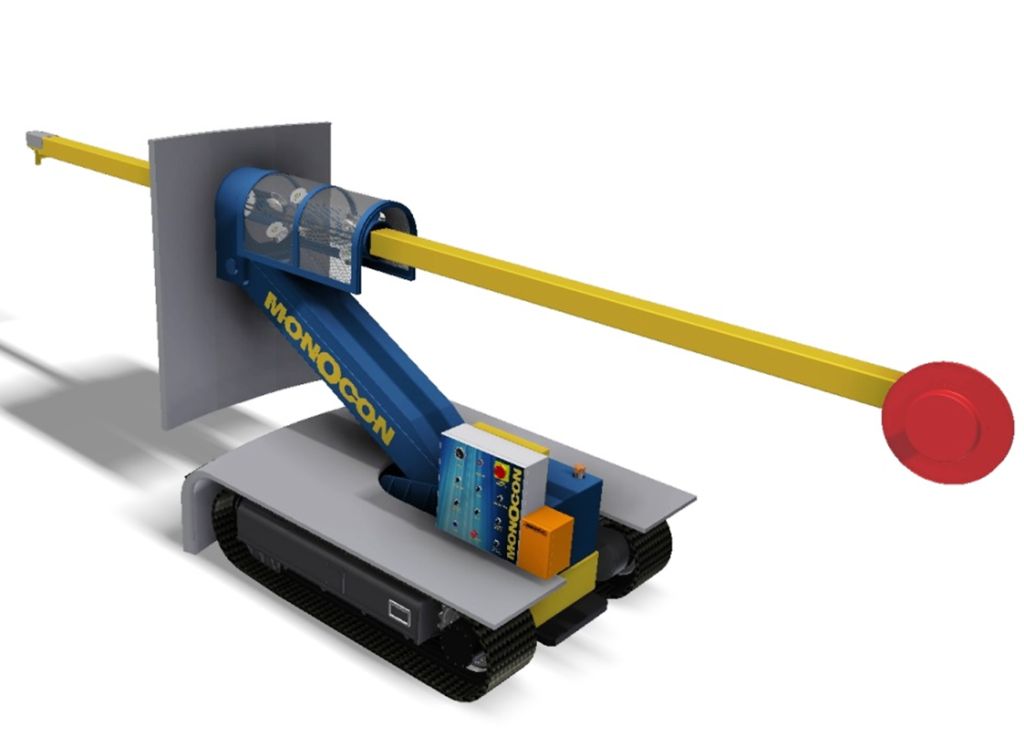

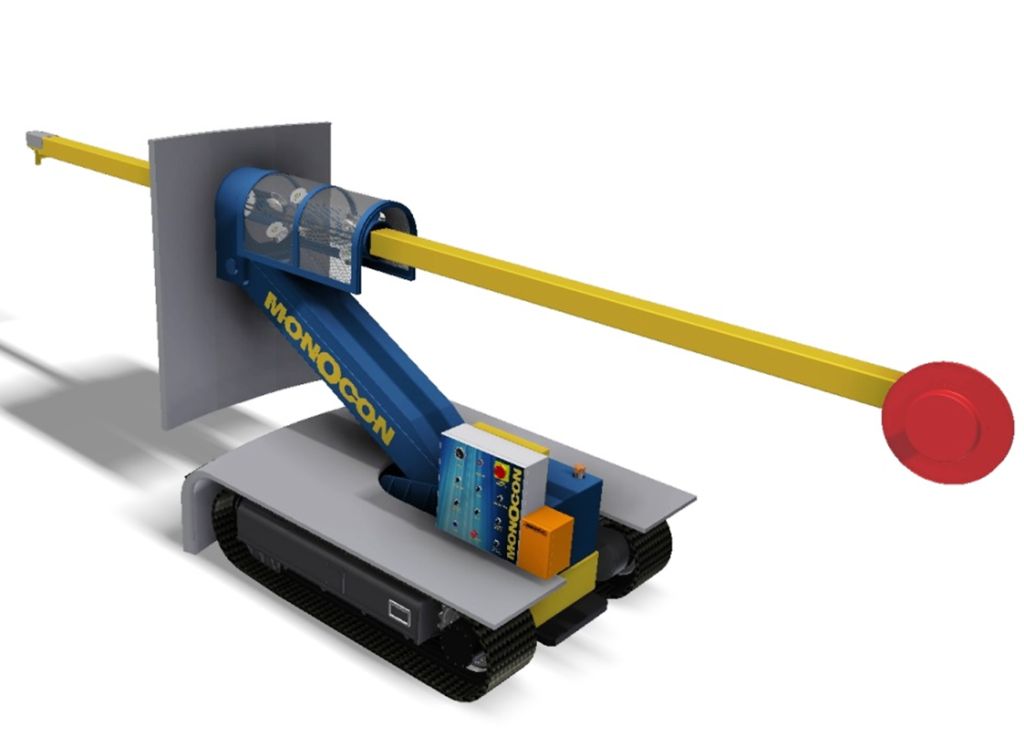

Monocator-Mobile Design Features

- Radio controlled joystick application of gunning material to the slagline, sidewalls of the ladle as well as the ladle bottom and specific areas of interest such as the well blocks, Impact Pad areas.

- Lightweight, user friendly joystick.

- Consistent material application.

- Extremely maneuverable due to the use of hydraulically powered “tracks”.

- Integral Material Feed System.

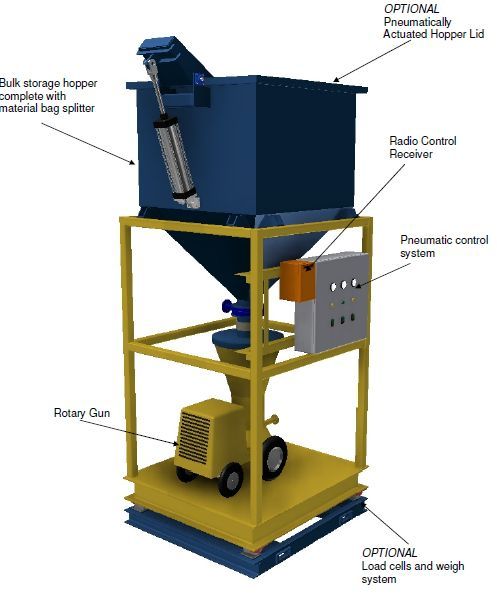

- Integral Bulk Hopper - 3 Tonnes.

- Bulk Hopper outlet has butterfly valve.

- Storage Chamber.

- Material feed Gun.

Safety Benefits

Monocator-Mobile Safety Benefits

- The radio controller functionality ensures that the operator is positioned remotely from the application / heat source and moving machinery.

- Emergency Shut-off

- No crane required during maintenance

Monocon provide a multitude of safety interlock facilities to enable safe use of the equipment. These interlocks are incorporated into the PLC operation. Safety systems are to be determined with customer but will typically include; Monocator Movement, Ladle Geometry, Emergency Stops and Low Pressure. The Monocator-Mobile can be arranged to perform agreed movements in response to specific Ladle repair events.

Technical Features

Monocator-Mobile Technical Features

Monocator-Mobile Technical Features

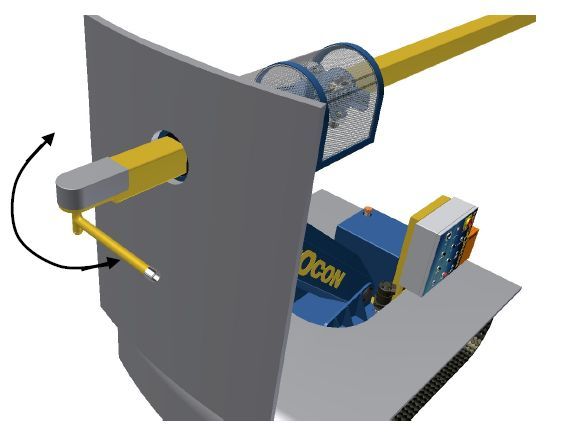

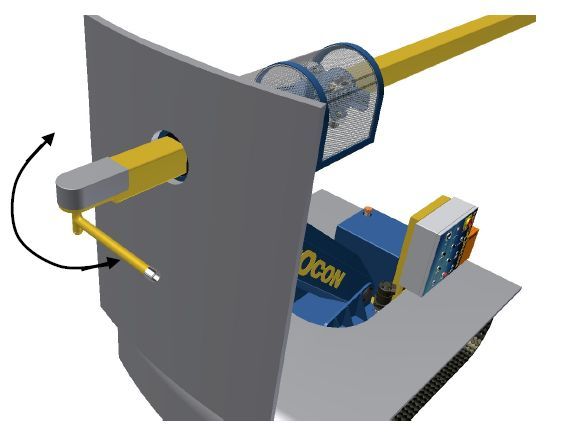

The “Monocator - Mobile “has the following axes of movement;

- Left and Right Track

- Slew: 180⁰

- Raise/Lower: 1100mm to 3000mm

- Tilt: (+15⁰ - Horizontal - 15⁰)

- Beam Telescope: 6 metres

- Rotate: Continuous 360⁰

- Nozzle: 180⁰

All axes listed are powered from an on board hydraulic power pack driven by a diesel engine. The unit comprises of;

- 10kw Diesel Engine and Piston Pump

- Bell Housing and Flexible Drive Coupling

- Hydraulic Reservoir and Filtration System

- Tank Accessories

The machine is a fabricated mild steel construction with access covers where necessary.

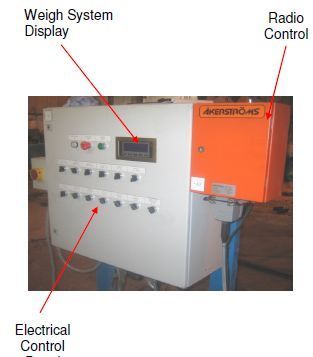

The Electrical Control System will typically consist of the following:

- PLC Panel - typical supply; 220/110V single phase

- Control Console - typical supply; 220/110V single phase

- Inverter Panel - typical supply; 415V, 3 Phase, 50 Hz

- Wireless Radio Controlled Joystick

- PLC based Electrical control panel: Standard is Mitsubishi PLC. (Other options are available)

- Integral Material Feed System: 2.0 cubic metres Bulk Hopper, with 6 Barg Pressure Vessel and material Delivery of 5.0 cubic metres/hour (max)

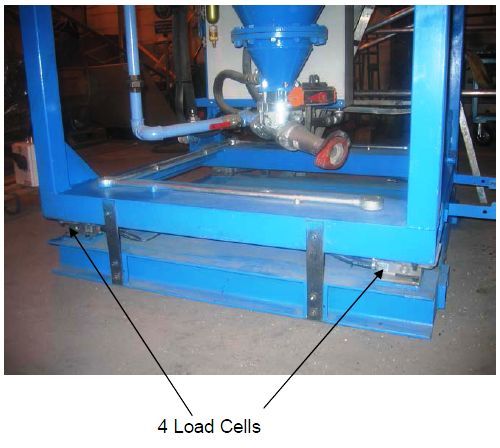

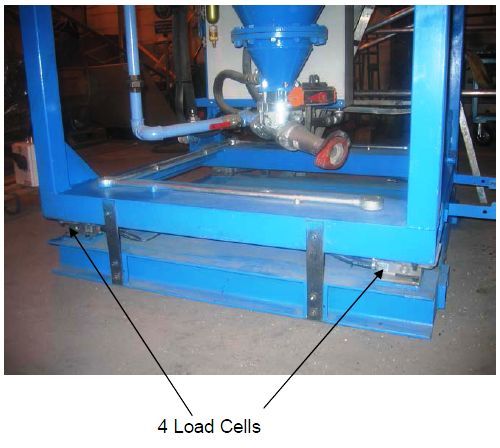

- Integral Weigh System: Display quantity of dry material, Optional Load Cells on Feed System. Digital Display on Control Panel

- Integral Water system: 200 Litres capacity, Multi-stage pump with control valve, digital flow meter and temperature control.

Onsite Services Required

- Electrical: - 415V, 3 PH, 63A

- Pneumatic:-90 PSI (6 bar), 8m3/min Maximum, 50mm Bore Supply

- Water: - City Water Supply

- Diesel fuel for Vehicle Diesel engine

- All services are to be provided in close proximity to the material feed system

Supply Options

Moncator-Mobile Supply Options

Moncator-Mobile Supply Options

- The Monocator-Mobile can be configured and/or customised to suit the clients requirements.

- All surfaces can be painted in accordance with the customer specification

- Dual Material Feed Systems - The machine can be supplied with two feed systems (either Pressure vessel or Rotary Gun) which will allow easy change of the spray material for different areas of the ladle as required.

- Alternate PLC Panel options are available such as an Allen Bradley unit with Ethernet/IP protocol or Siemens PLC with Profinet.

- UPS - mains power spike/failure protection

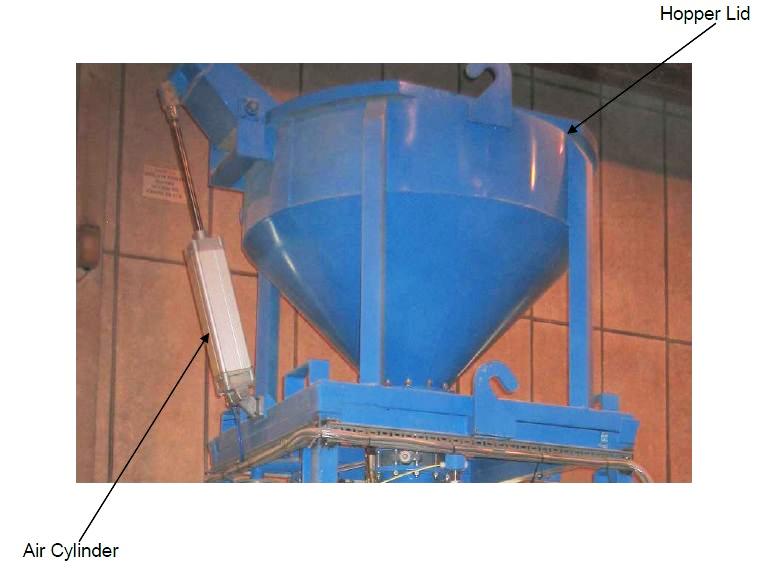

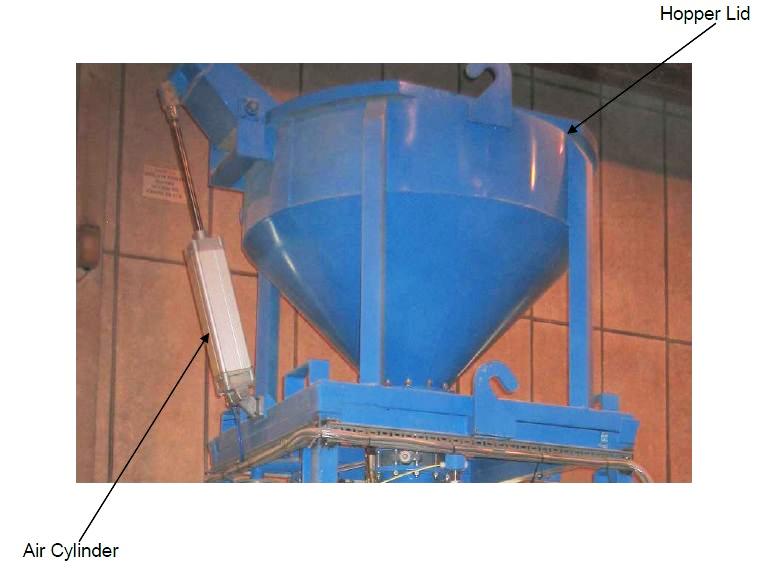

Pneumatically operated Hopper lid to prevent the ingress of foreign bodies.

Pneumatically operated Hopper lid to prevent the ingress of foreign bodies.- Load Cells on the Hopper System

Please contact our UK technical team for further information.

Monocator-Mobile Operational Benefits

Monocator-Mobile Operational Benefits

Monocator-Mobile Technical Features

Monocator-Mobile Technical Features Moncator-Mobile Supply Options

Moncator-Mobile Supply Options Pneumatically operated Hopper lid to prevent the ingress of foreign bodies.

Pneumatically operated Hopper lid to prevent the ingress of foreign bodies.