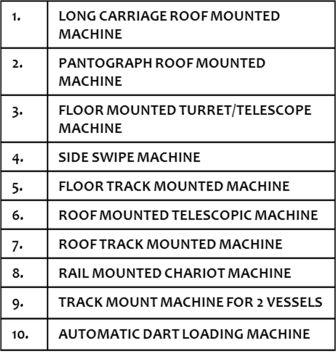

Type 1

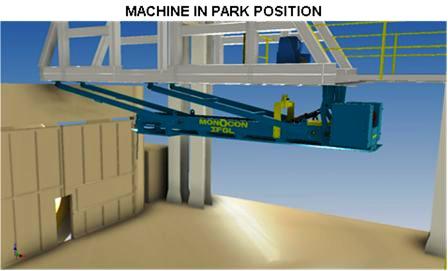

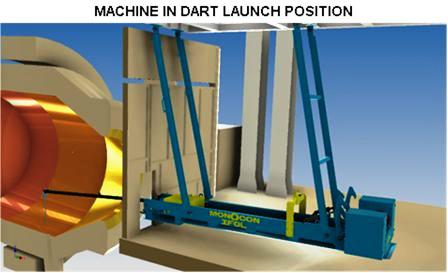

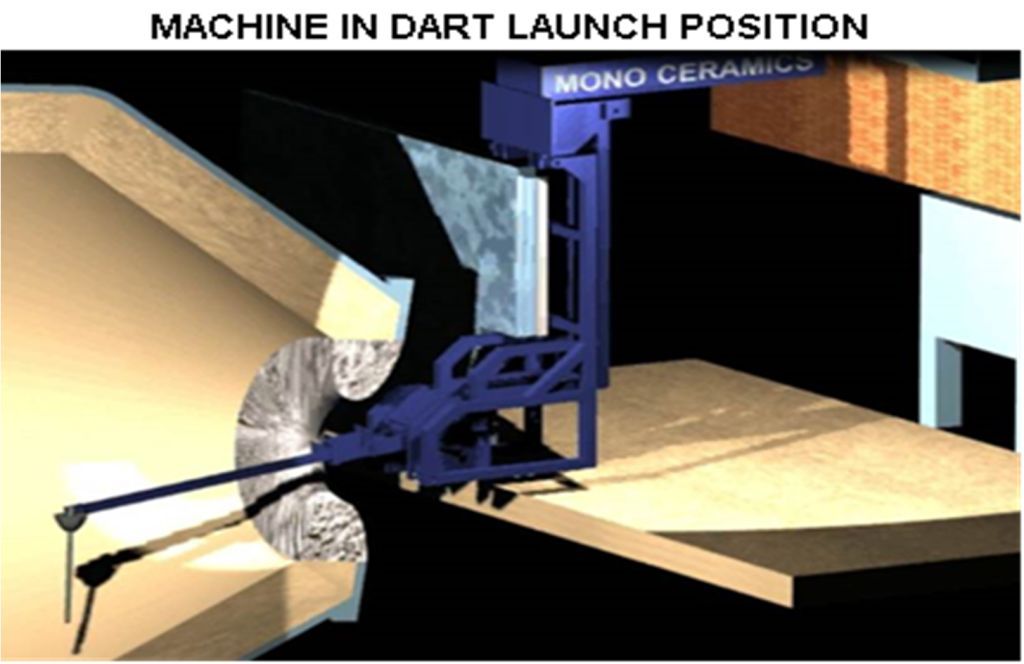

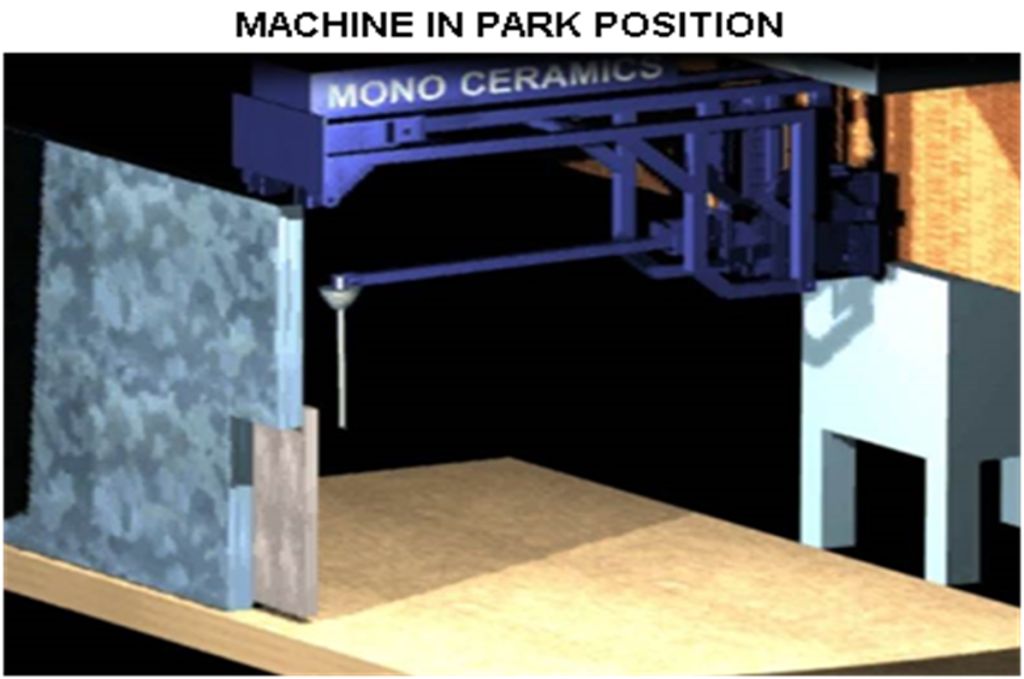

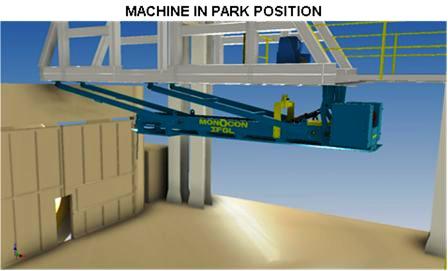

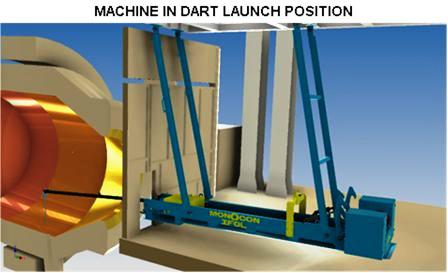

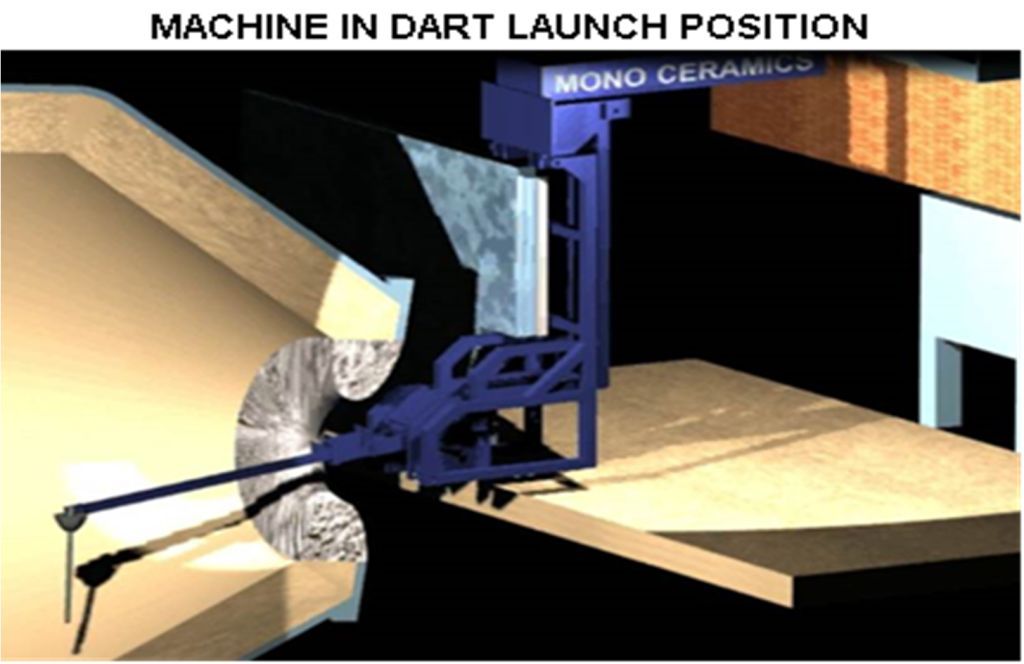

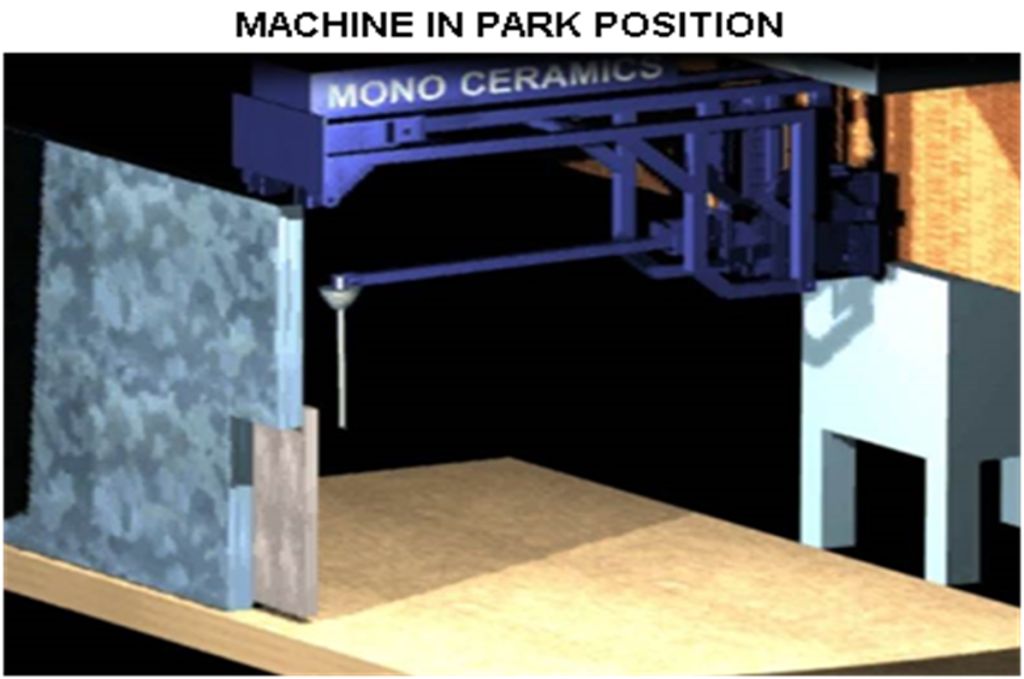

Long Carriage Roof Mounted Dart Machines

Long Carriage Roof Mounted Dart Machines

Monocon's Type 1 Dart machine is a long carriage, roof mounted machine design as shown to the right.

At the end of 2016, Monocon had supplied 15 of this type of dart machine to six steel plants around the world.

As shown, when the dart machine is in its 'park position' it is tucked up in the roof space allowing clear operational access at floor level. In operation, the suspension arms lower the dart machine into position so that it can extend and drop the dart through the access opening and into the furnace. Click here to see the standardised dart machine features.

Type 2

Pantograph Dart Machines

Pantograph Dart Machines

Monocons Type 2 dart machine is a pantograph, roof mounted machine design as shown.

At the end of 2016, Monocon has supplied 4 of this type of dart machine to two steel plants around the world

.

Type 3

Turret/Telescope Dart Machines

Monocon's Type 3 dart machine is a floor mounted turret/telescope machine design as shown.

At the end of 2016, Monocon has supplied 22 of this type of dart machine to ten steel plants around the world.

Type 4

Side Swipe Dart Machines

Monocon's Type 4 dart machine is a side swipe machine design as shown.

At the end of 2016, Monocon has supplied 11 of this type of dart machine to five steel plants around the world.

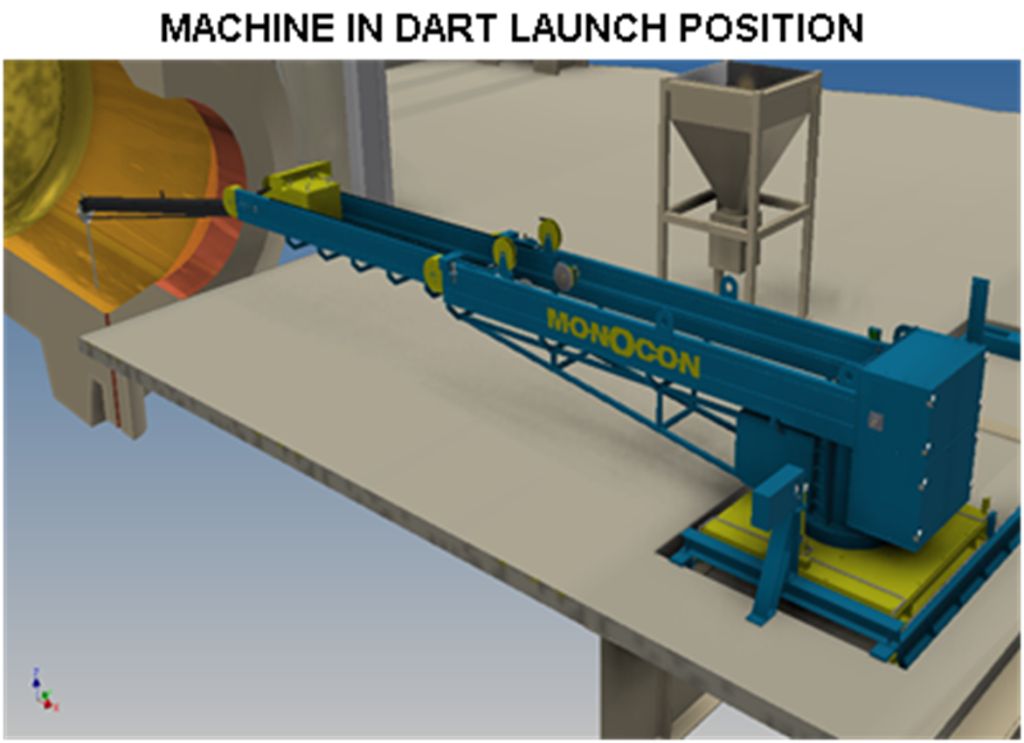

Type 5

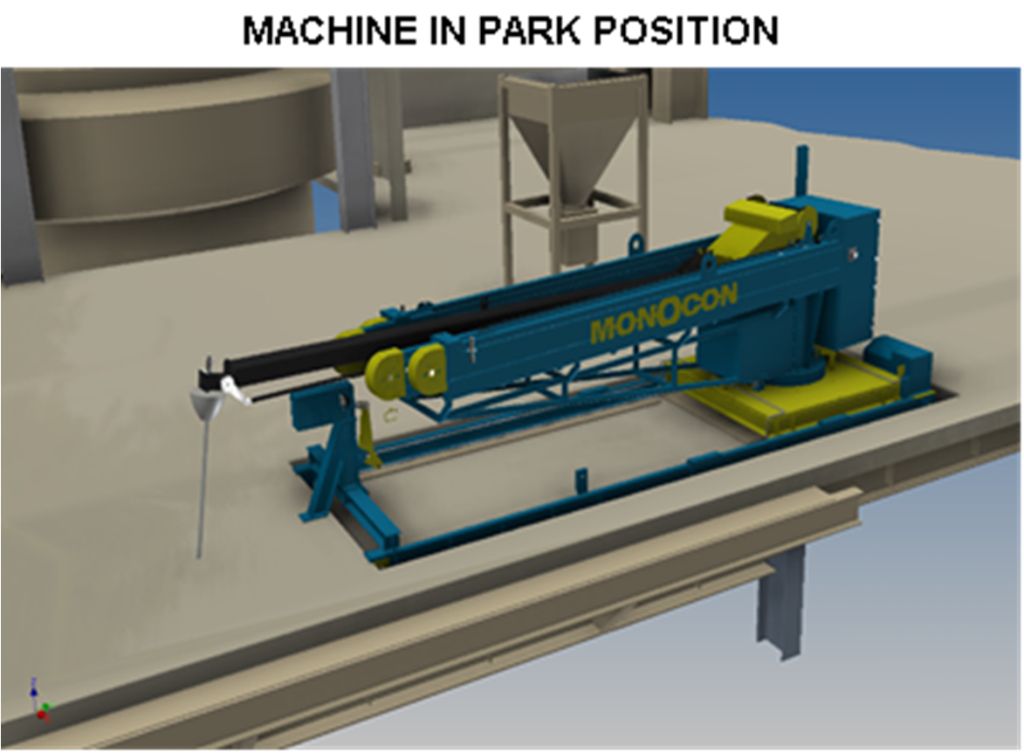

Floor Track Mounted Dart Machines

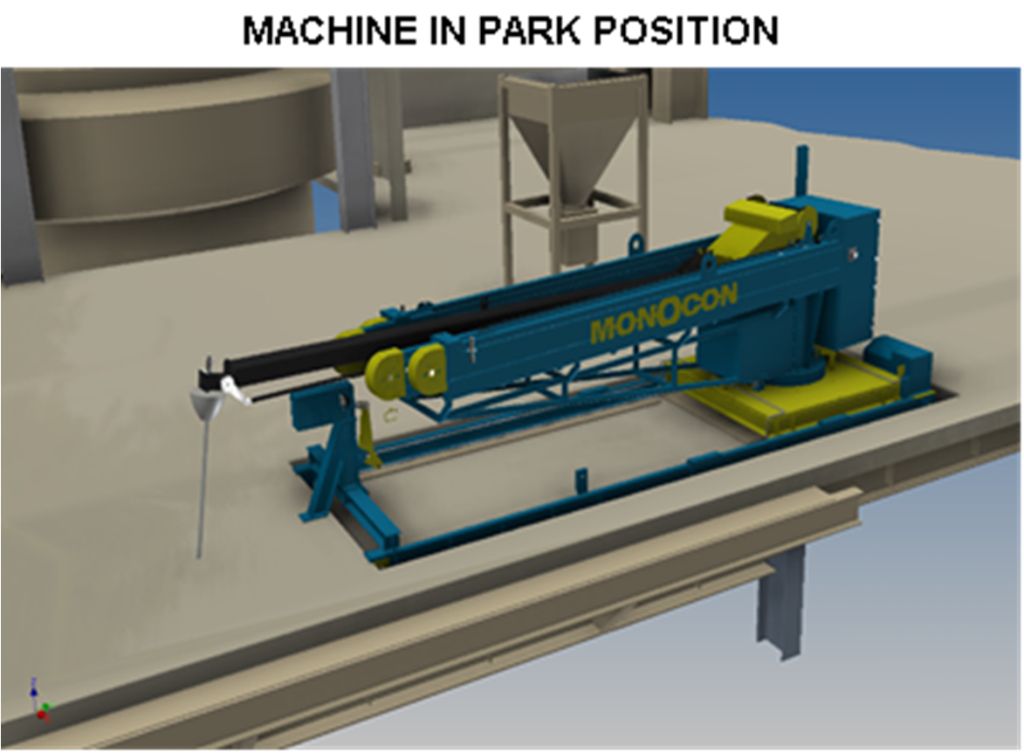

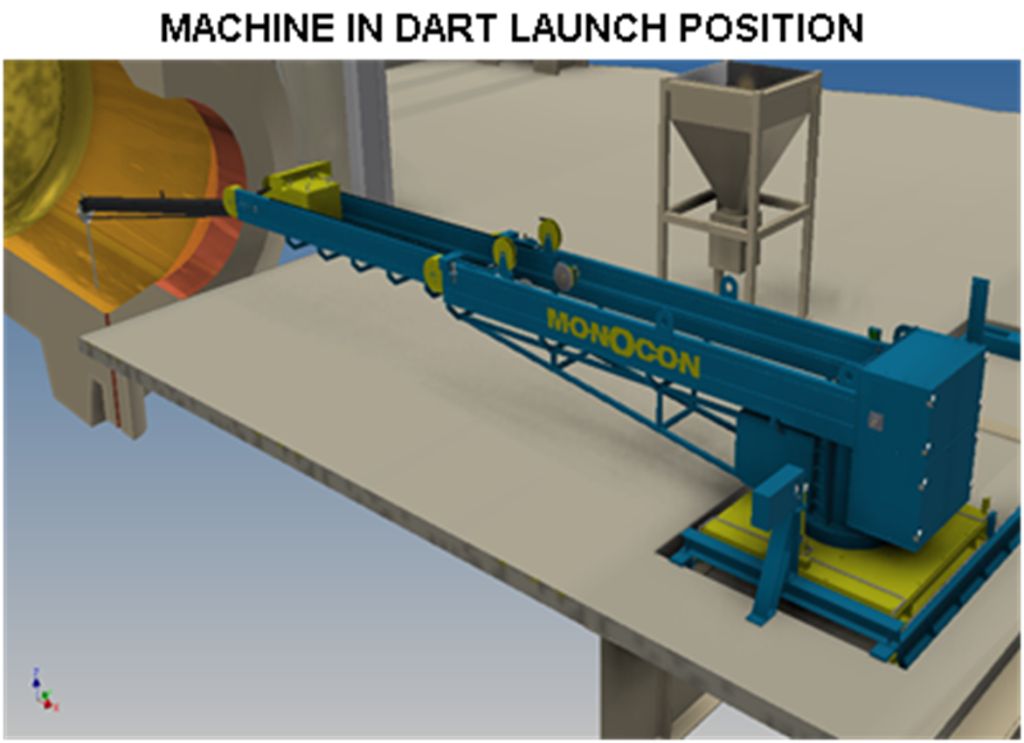

Monocon's Type 5 dart machine is a floor mounted track machine design as shown.

At the end of 2016, Monocon has supplied 4 of this type of dart machine to two steel plants around the world.

Type 6

Roof Mounted Telescopic Dart Machines

Monocon's Type 6 Dart machine roof mounted telescopic machine design as shown to the right.

At the end of 2016, Monocon has supplied 4 of this type of dart machine to two steel plants around the world.

Type 7

Roof Track Mounted Dart Machines

Monocon's Type 7 dart machine is a roof track mounted machine design as shown.

At the end of 2016, Monocon has supplied 5 of this type of dart machine to two steel plants around the world.

Type 8

Rail Mounted Chariot Dart Machines

Monocons Type 8 dart machine is a rail mounted chariot machine design as shown.

At the end of 2016, Monocon has supplied 3 of this type of dart machine to one steel plant.

Type 9

Floor track mount telescope machine for 2 Vessels

Floor track mount telescope machine for 2 Vessels

Monocon's Type 9 dart machine is a Floor track mount telescope machine design for 2 Vessels as shown.

At the end of 2016, Monocon has supplied 1 of this type of dart machine to one steel plant

.

Design Features

Generic Dart Machine Design Features

Our Monocon dart loading machines are typically used with certain types of Slag Dart machines in steel plants who look for a turnkey supply solution for slag control. A special dart cassette is used to transport a number of pre-assembled darts to the operations floor. The special dart cassette is placed adjacent to the Dart Machine and following the insertion of a dart into the furnace the dart machine is re-loaded with a new dart ready for the next heat.

Op.Benefits

Generic Dart Machine Operational Benefits

- Accurate and repeatable dart holding and positioning in the ladle.

- Electric motor driven movement.

- Minimum manual/human activities on shop floor.

- Increased productivity.

- Improved steel quality.

- Constant monitoring of the system status i.e. maintenance, fault diagnosis.

- Heavy duty construction = long lasting machines.

- Monocon technical and service back-up.

Safety

Generic Dart Machine Safety Benefits

- Dart loading machine ensures that the operator is positioned remotely from the application/heat source and moving machinery.

- Minimal manual lifting or intervention which can cause possible injury.

- Emergency Shut-off.

- Optional customised guarding to suit customer requirements/physical constraints.

Monocon provide a multitude of safety interlock facilities to enable safe use of the equipment. These interlocks are incorporated into the PLC operation. Safety systems are to be determined with customer but will typically include; Dart Machine Movement, Ladle Geometry, Emergency Stops and Failed Dart Loading.

Technical

Generic Dart Machine Technical Features

- XYZ axis movement of dart via heavy duty electric drive motors.

- The machine is a fabricated mild steel construction with access covers where necessary.

- Designed to be used in conjunction with Monocon Darts. (Alternate dart designs considered where required).

The Electrical Control System will typically consist of the following:

- PLC Panel - typical supply; 220/110V single phase.

- Control Console - typical supply; 220/110V single phase.

- Inverter Panel - typical supply; 415V, 3 Phase, 50 Hz.

- PLC based Electrical control panel: Standard is Mitsubishi PLC. (Other options are available).

Onsite Services Required

- Electrical: - 415V, 3 PH, 63A.

- Pneumatic:-90 PSI (6 bar), 8m3/min Maximum, 50mm Bore Supply.

- All services are to be provided in close proximity to the material feed system.

Options

Generic Dart Machine Supply Options

- The Dart Loading Machine can be configured and/or customised to suit the clients requirements.

- All surfaces can be painted in accordance with the customer specification.

- Customised machine guarding to suit customer requirements/physical constraints.

- Alternate PLC Panel options are available such as an Allen Bradley unit with Ethernet/IP protocol or Siemens PLC with Profinet.

- UPS - mains power spike/failure protection.

Please contact our UK technical team for further information.

Monocon has developed and supplied many dart machines for clients operating in the steel and metals industry all around the world including UK, Mexico, USA, Russia, Australia, Sweden, India, Brazil, Ukraine, Taiwan, Turkey, Algeria, Chile, New Zeland and The Netherlands to name just a few. At the end of 2016, Monocon had supplied over 90 Dart Machines to almost 40 Steel making plants throughout the world.

Monocon has developed and supplied many dart machines for clients operating in the steel and metals industry all around the world including UK, Mexico, USA, Russia, Australia, Sweden, India, Brazil, Ukraine, Taiwan, Turkey, Algeria, Chile, New Zeland and The Netherlands to name just a few. At the end of 2016, Monocon had supplied over 90 Dart Machines to almost 40 Steel making plants throughout the world.

Long Carriage Roof Mounted Dart Machines

Long Carriage Roof Mounted Dart Machines

Pantograph Dart Machines

Pantograph Dart Machines

Floor track mount telescope machine for 2 Vessels

Floor track mount telescope machine for 2 Vessels