V1 Design Features

MSTM-V1 Design Features

MSTM-V1 Design Features

The MSTM-V1 is a compact design, semi-automatic ladle shroud manipulator which is manually positioned and has powered shroud rotate and raise/lower functions. The machine consists of the following main components:

- Monocon Shroud Tube Manipulator V1 (MSTM-V1).

- Hydraulic Power Unit.

- Electrical Control Console - PLC Control Panel to house the PLC along with associated power supply and Ethernet connection.

V1 Operational Benefits

MSTM-V1 Operational Benefits

MSTM-V1 Operational Benefits

- Good operational flexibility using semi-powered machine.

- The MSTM is free moving so that when the machine is in “Dock” mode, there is no resistance to the slide gate operation. This is integral to ensuring correct operation of the gate and maintaining alignment of the ladle shroud.

- The ladle can be raised and lowered (where applicable) with the machine in “Dock” and the pre-set force will still be maintained with the shroud in position.

V1 Safety Benefits

MSTM-V1 Safety Benefits

MSTM-V1 Safety Benefits

Safe equipment and operation is paramount. The Monocon MSTM-V1 machine is built to the latest applicable standards. Full training in all aspects of the equipment and operation will be provided as part of our Monocon quality assurance machine commissioning program.

- Emergency Shut-off.

- Semi-powered lifting and manipulation reduces manual intervention, lifting and/or undue strain.

Monocon provide a multitude of safety interlock facilities to enable safe integration with the caster operation. This interlock will be incorporated to the PLC operation. Safety systems are to be determined with customer but will typically include; Ladle Movement, Tundish Movement, Emergency Stops and Low Pressure. The MSTM-V1 can be arranged to perform agreed movements in response to specific caster events and vice versa.

V1 Technical Features

MSTM-V1 Technical Features

MSTM-V1 Technical Features

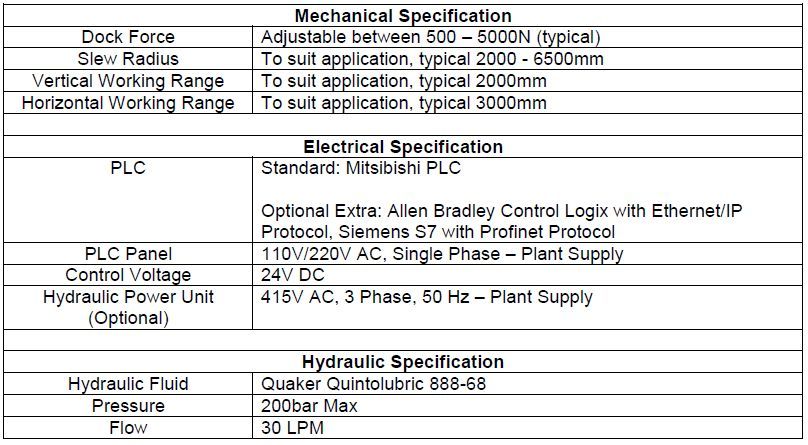

The machine is a fabricated mild steel construction with access covers where necessary. The MSTM-V1 is mounted on a base plate which will be fixed in place on the caster floor.

The Electrical Control System will typically consist of the following:

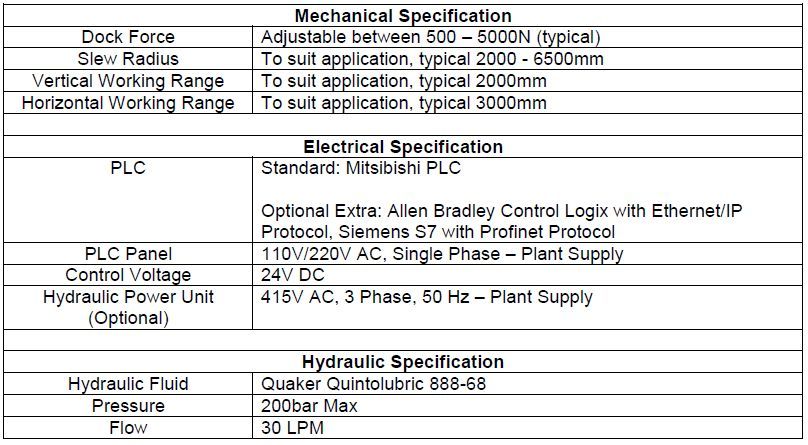

- PLC Panel - typical supply; 220/110V single phase.

- Control Console - typical supply; 220/110V single phase.

The Hydraulic power pack will use an appropriate flame proof safe lube.

V1 Movement Features

MSTM-V1 Movement Features

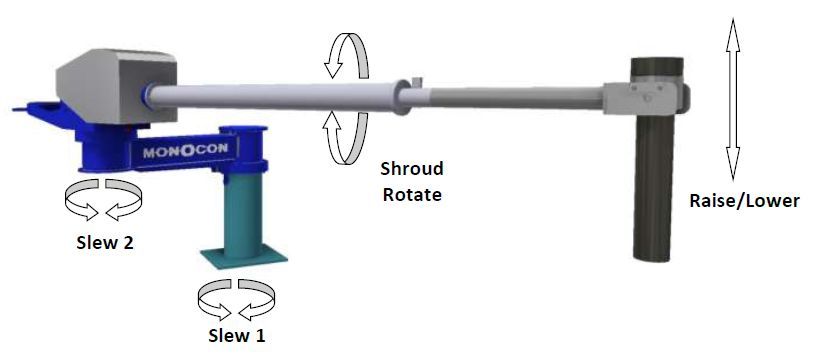

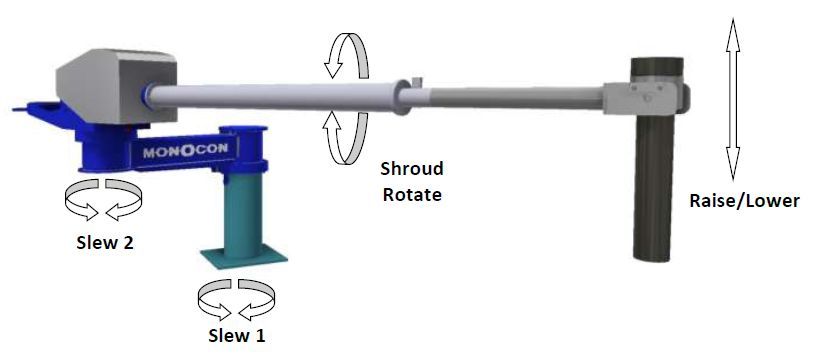

An articulated jib with two slew bearings provides the slew with the forward/backward movement and the boom can be raised/lowered and rotated to allow correct positioning of the shroud.

- Slew 1 - Manual movement.

- Slew 2 - Manual movement.

- Boom Rotate - Hydraulic driven movement.

- Boom Raise/Lower - Hydraulic driven movement.

The MSTM-V1 is moved between the following positions:

- Park: a safe park position of the MSTM-V1 away from the movements of the tundish and ladle.

- Load: a position from which the shroud can be loaded.

- Dock: the shroud is held with an upwards force from the raise/lower cylinder against the collector nozzle. The force will be maintained at a pre-set docking pressure to hold the shroud position during casting. Typically the dock force is adjustable between 500-5000N.

- Burnout: a position to allow the safe lancing of the ladle shroud or positioning under an automatic burnout station (where applicable).

V1 Supply Options

MSTM-V1 Supply Options

- The Monocon Shroud Tube Manipulator V1 can be configured and/or customised to suit the clients requirements.

- Available in a fully automatic variant (see MSTM-V2).

- Optional Hydraulic Power Unit (See the image on the right). This unit is supplied as a 'plug-and'play' framed assembly including all the integral filters and componentary.

- All surfaces can be painted in accordance with the customer specification.

- Monocon can provide vibration sensors in the Shroud Tube Manipulator to provide early detection of slag flow in the shroud tube. This optional supply feature thereby provides an early-warning system which can significantly contribute to improving the quality of the steel produced.

-

The Shroud Support Ring (example shown to right), can be designed to suit customer requirements. This can include open or closed ring design and must be determined prior to order. The holder fork connects the Shroud Support ring to the boom. It is designed to be replaceable in case of damage due to steel splashing. The section should be kept on stock as a spare at all times.

- Alternate PLC Panel options are available such as an Allen Bradley unit with Ethernet/IP protocol or Siemens PLC with Profinet.

- UPS - mains power spike/failure protection .

Please contact our UK technical team for further information.

In steel making, the shroud tube creates a connection between the ladle and tundish of the continuous casting plant allowing molten metal to flow between the two. The Monocon Shroud Tube Manipulator (MSTM) guides this shroud tube to controlled the delivery of the liquid steel from the ladle into the tundish to improve the steel quality and increase process reliability.

In steel making, the shroud tube creates a connection between the ladle and tundish of the continuous casting plant allowing molten metal to flow between the two. The Monocon Shroud Tube Manipulator (MSTM) guides this shroud tube to controlled the delivery of the liquid steel from the ladle into the tundish to improve the steel quality and increase process reliability. MSTM-V1 Design Features

MSTM-V1 Design Features

MSTM-V1 Operational Benefits

MSTM-V1 Operational Benefits MSTM-V1 Safety Benefits

MSTM-V1 Safety Benefits MSTM-V1 Technical Features

MSTM-V1 Technical Features