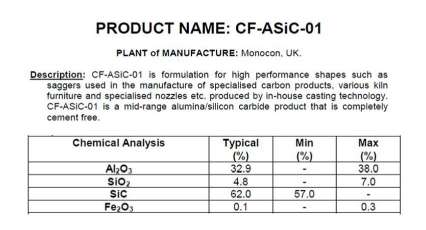

Activated Gel Casting (AGC)

• AGC is a significant new precast technology for the Monocon Group

• Its success is a combination of materials selection, bond activation and a unique manufacturing process

• AGC recipes are completely cement free

• AGC produces products with higher strength, thermal shock resistance, erosion/corrosion resistance when compared with equivalent conventional castables

The Benefits:

• Higher performance vs equivalent conventionally cast pieces

• Commercial savings vs conventional cast for same performance

• Flexible manufacture offering the capacity to cast larger refractory items to small complex shapes

Fact – All AGC Materials are Completely Cement Free – Why is this an advantage?

|

Conventional Castables • Contain Cement |

AGC Castables • Cement Free |

AGC (CF) Castables

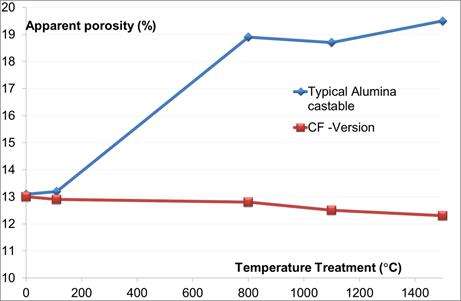

Comparison Graph – Cementitious Vs Cement Free Refractory – Apparent Porosity

AGC Product Applications List

AGC Product Applications List

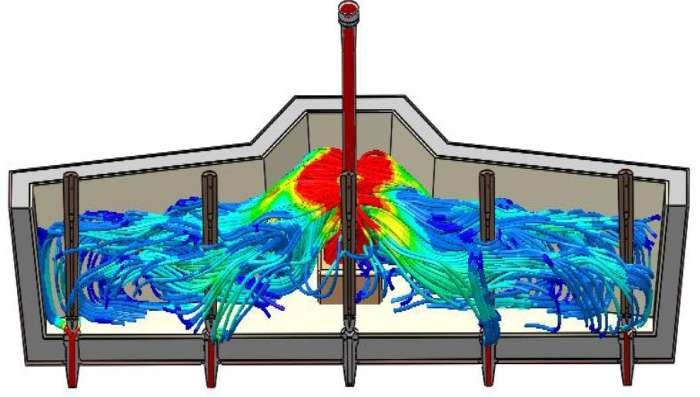

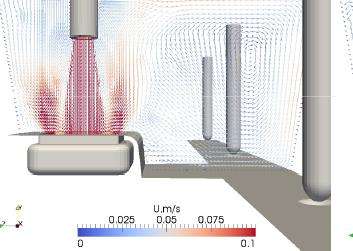

• Monobox (Tundish Flow Modifier)

• Ladle Slide / Rotary Gate Exchangeable Collector Nozzles

• Ladle Upper, Lower Nozzles

• Purging Plugs

• Ladle Plug and Well Blocks

• Lance Sleeves

• Tundish Nozzles

• Foundry Products

• Ladle Well Block Upper, Lower Nozzles / Plug Support Blocks

• Saggars & Crucibles

• Re-Heat Furnace Products - AGC Hearth Blocks

• Increased steel residence time

• Increased steel residence time