Monocon's sister company, EI Ceramics, has supplied this type of gasket to steel plants in North America and Europe for many years.

Monoplas Gaskets are now also manufactured by Monocon in the UK and supplied to customers around the world.

With excellent performance in the field and a shelf life in excess of 6 months, Monocon specialise in offering individual designs for each customer application.

Monoplas Design Features

Monoplas Design Features

The Monocon Monoplas design features include;

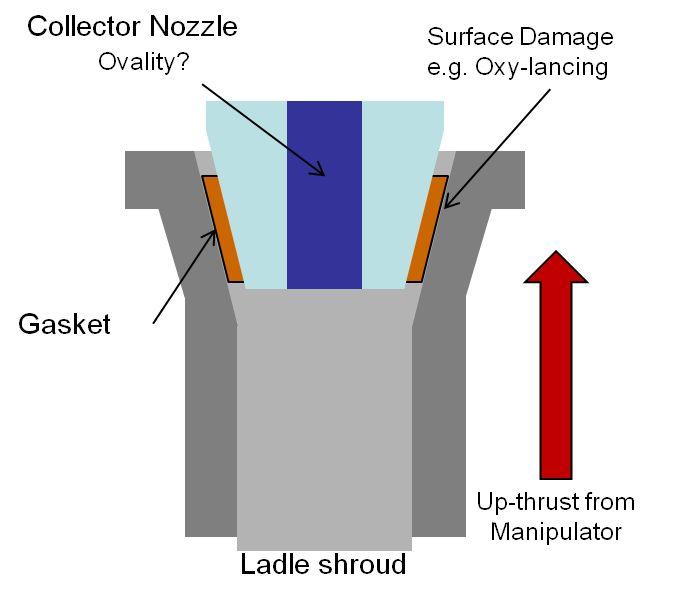

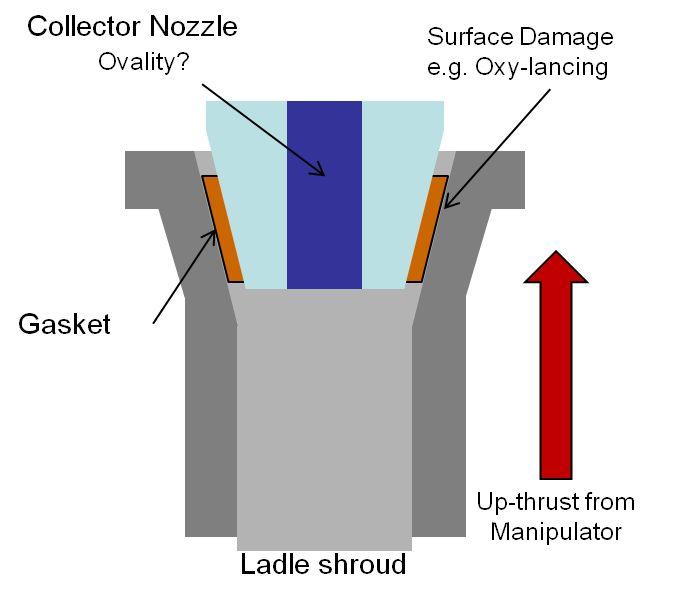

- Designed specifically for installing onto the Collector Nozzles.

- An internal and external graphite coating.

- Can be adapted for other sealing applications.

- Robust material of construction.

- Easy to Install .

Monoplas Operational Benefits

Monoplas Operational Benefits

Monoplas Operational Benefits

- Monocon Monoplas gaskets act as load spreaders to minimise flange cracking.

- The ability of the gummy material to flow under pressure results in a better seal in all cases, especially if the inner cone area is worn or damaged.

- The Monoplas gaskets are impervious and when installed correctly result in lower Nitrogen pick-up levels.

- Correctly applied gummy gaskets can significantly reduce the amount of Argon required.

- Significant improvements in steel cleanliness are possible by the prevention of re-oxidation due to air ingress. This can reduce downstream SEN clogging and can result in improved disconnection of the LS from the CN resulting in less damage to both the shroud and nozzle, can promote cost savings through the increased lifetimes achievable with the Collector Nozzles.

Monoplas Operational Benefits

Monoplas Operational Benefits